A. DOGR Technologies Commercialized

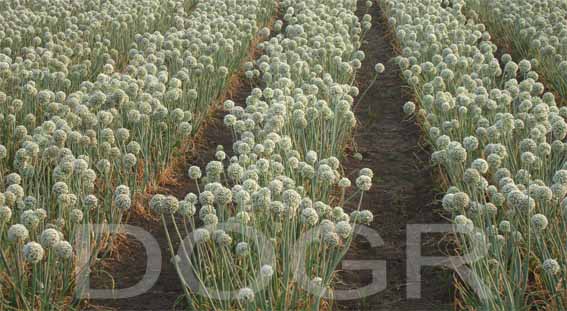

1. Kharif Onion Production Technology

Kharif season is characterized by heavy rain fall which leads to poor drainage and diseases like anthracnose, purple blotch and Stemphylium blight. The technology includes combination of following practices to reduce the drainage and disease problem and raise healthy crop.

Raising nursery during second fortnight of June on broad bed furrow with drip or sprinkler irrigation under shade nets and keeping the seedlings ready for transplanting in the first fortnight of August.

Transplanting of seedlings on broad bed furrow with drip or sprinkler irrigation. The raised bed in broad bed furrow facilitates quick and efficient drainage of rainwater, which minimizes the incidence of soil borne and foliar diseases.

Application of 75:40:40:20 kg NPKS/ha + organic manure equivalent to 75kg N/ha is recommended for kharif.

Application of Azospirillum and phosphorus solublizing bacteria at 5kg each per ha is recommended.

Full of PKS and 1/3 of N need to be applied at the time of transplanting and remaining 2/3 of N in two equal splits at 30 and 45 DAT.

Application of FYM or Vermicompost pre-mixed with Trichoderma viride before bed preparation, It helps in reducing the incidence of soil borne diseases.

Fertigation through drip avoids leaching losses of nutrients, which is common in high rainfall conditions: 2/3 of top dressing N needs to be applied in seven splits at weekly interval from transplanting to 60 DAT.

Application of pre-emergence herbicide pendimethalin @0.2%.

This technology ensures 25 tons of yield per hectare without compromise in quality of bulbs.

2. Micro Irrigation for Onion and Garlic

For drip irrigation, seedlings need to be planted at a spacing of 10 x 15 cm in a broad bed furrow (BBF) of 15 cm height and 120 cm top width with 45 cm furrow. Each BBF should have two drip laterals at (16 mm size) 60 cm distance with inbuilt emitters. The distance between two inbuilt emitters should be around 30-50 cm and the discharge flow rate is 4 l/hr.

For sprinkler, the distance between two laterals (20 mm) of micro sprinkler should be 6 m and with a discharge rate of 135 l/hr.

Drip irrigation at 100% Pan Evaporation (PE) significantly improved the marketable bulb yield (15-25%) with higher per cent A grade bulbs, water saving of about 35-40% and labour saving of 25-30%.

3. Fertigation

-

Fertigation is an effective and efficient method of applying fertilizers though drips irrigation system along with irrigation water. Drip irrigation system is used as the carrier and distributor of irrigation water and crop nutrients.

-

Application of fertilizers @ NPK 40:40:60 kg /ha as basal and the remaining 70 kg N in seven splits through drip irrigation is recommended for achieving higher marketable bulb yield and cost benefit ratio.

-

Splits doses should be applied at weekly interval from transplanting to 60 DAT

Drip irrigation system not only helps in water saving but also reduces nitrogen losses by leaching into ground water as in fertigation fertilizer nutrients are applied in root zone only.

4. Weed management in onion

-

Application of 0.2% Oxyflurofen 23.5 % EC before planting + one hand weeding at 40-60 days after transplanting is recommended for marketable bulb yield and weed control efficiency (65-80%).

5. Integrated Nutrient Management for Sustainable Rabi Onion

-

Combined application of 110:40:60:20 kg NPKS along with organic manures equivalent to 15 t FYM and Azospirillum and Phosphorus solubilizing bacteria @ 5 kg each/ha.

Besides the high yield and cost benefit ratio, soil available nutrient status after harvest increases. By adopting this recommendation, the use of costly inorganic fertilizers can be reduced by 25 %.

6. Integrated Pest and Disease Management

-

Follow crop rotation by non host crops (corn and millets) and clean cultivation by destroying plant debris of previous season.

-

Use of drip irrigation over conventional irrigation to avoid disease outbreaks.

-

Provide good drainage through raised beds in Kharif to minimize soil borne diseases

-

Seed treatment with Thiram + Carbendazim (2:1) @ 3g/kg seed or Trichoderma spp. @ 4-6 g/kg seed

-

Multiply 2 kg of Trichoderma spp. in 1 quintal of FYM and apply in one hectare.

-

Dip the seedlings in 0.025% carbosulfan + 0.1% carbendazim solution for 2h before transplanting in the main field

-

Plant 2 rows of maize or outer row of maize and inner row of wheat surrounding onion crop (250sq.m) at least 30 days prior to transplanting to block adult thrips

-

Initiate foliar sprays of pesticides from 30 days after transplanting or as soon as the pest/disease appears in the field

-

Spray insecticides when thrips population crosses economic threshold level (ETL) i.e. 30/plant

-

Spray fungicides and pesticide in combination for effective management of pest and diseases. Spray Schedule includes Mancozeb @ 0.25% with Methomyl @ 0.8 g/l at 30 days after transplanting, Tricyclazole @ 0.1% with Carbosulphan @ 2 ml/l at 45 days after transplanting, Hexaconazole @ 0.1% with profenofos @ 1 ml/l at 60 days after transplanting. However if disease/pest incidence is higher, then one additional spray of any of the above combination should be taken

-

Spray at 10-15 days interval depending on insect pest /disease intensity

-

Always add spreader @ 0.5-1.0%

-

Avoid repeated application of pesticide belonging to same class

7. Seed Production

For maintaining high seed vigour and viability, onion seeds should be treated with thiram and stored in 400 gauge poly pack.

Seed priming with 2% K2HPO4 for 24 hours at 150C enhances the seedling vigour and seed viability.

Pre-harvest prophylactic spray of fungicide Quintal ® (Iprodione + Carbendazim) during seed development is most effective in controlling the seed infection.

Vernalization Treatment of bulbs for 10 days at 15 0C before planting enhances the seed yield.

8. Manually operated onion grader

This is a double roller type grader, which grades onion on the basis of diameter. Total weight of the grader is around 125 kg and it can be moved across the fields with its caster wheels. The height of the hopper is around 5 feet, which makes it convenient for loading onions. The grader is 6 feet in length and 2 feet wide and can be accommodated in little space.

The grader has provision for grading onion in five grades (<35mm, 35 –50 mm, 50 – 60mm, 60 –80mm and > 80 mm) according to the size of onions.

The grader can be used for grading of many other fruits and vegetables such as sweet orange, sapota, limes, lemon etc.

9. Motorized onion grader

The motorized grader has 2 sets of counter rotating double rollers, which grades onion on the basis of diameter. Total weight of the grader is around 300 kg. The grader has one 1HP motor for rotating the rollers. It has provision of grading onion in five grades i.e. <35mm, 35 –50 mm, 50 – 60mm, 60 –80mm and > 80mm. The grader is 7 feet in length and 4 feet wide.

10. Storage Environment/ Structures:

- Low volume low cost onion structure: This storage structure is suited for 5 to 10 tons capacity.

- High volume bottom & side ventilated onion storage structure: The storage structure is suited for 25-50 tons capacity

- These storage structures reduce storage losses by 20-50% depending upon the period of storage.

B. Technologies for commercialization

1. RT-PCR kit for the detection of IYSV

A highly sensitive, simple and rapid detection kit developed to detect Iris Yellow Spot Virus (IYSV) in infected onion leaf samples

This kit has been validated by testing onion field samples from various geographical locations across India

2. One step RT-PCR kit for the detection of OYDV

A highly sensitive, simple one step detection kit developed to detect OYDV in infected onion and garlic samples.

The PCR protocol is rapid and throughput and can detect OYDV in the infected tissue within 2.0 h

This kit has been validated by testing onion field samples from various geographical locations across India.

3. One step quantitative real time RT-PCR kit for the detection of OYDV

An ultra sensitive one step SYBR Green based detection kit developed to detect OYDV in infected onion and garlic samples.

The protocol is a non-gel based protocol and results can be viewed real time.

The protocol involves cDNA synthesis and PCR in a single step.

This kit is validated by testing onion field samples from various geographical locations across India.